FluidWorker 150

Modern process fluid management

FluidWorker 150 ensures profitability through sustainable increased productivity and cost savings

- Higher machine availability, productivity, and quality

- Unproductive manual work is replaced by automation

- Longer service life for machines and tools

- Improved work environment through lower toxic exposure

- Sustainable production through extended fluid life

Automated process fluid quality

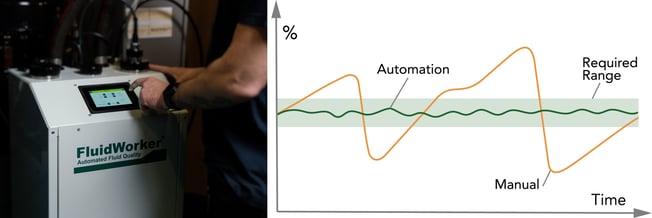

Automatic monitoring & control – The concentration (%) of the circulating process fluid is measured and adjusted automatically. An accompanying level sensor is installed in the tank, which ensures the correct level during production.

Reduction of bacteria – Using industrial UV light prevents bacterial growth without using biocides in process fluids. UV treats the liquid, which is circulated with a built-in pump.

Simple handling – UV, pump flow and desired concentration (%), and indications of lamp change and alarms are handled in the control system.

Self-cleaning – Patented cleaning of the UV lamp and BRIX sensor ensures function and minimal maintenance.

Filtration – Supplied with an integrated magnetic filter for cleaner fluid, more stable production, and less machine wear. For larger quantities of shavings, a self-cleaning inlet strainer is available as an option.

Industry 4.0 – With Ethernet connection and USB, measurement data and status information for monitoring, traceability requirements, and process development are provided.

Easy installation – The unit is compact and ready to use upon delivery. Connect electricity and water and fill with concentrate or use a separate barrel. Commissioning is done in less than an hour without stopping production.