Operators avoided respiratory problems and eczema

Sustainable development and healthy workers are crucial to Siemens. In 2009, one of the most important machines in Production was constantly affected by bacteria, necessitating a high dose of biocides. The staff also experienced respiratory problems and skin irritations.

Adding such a large quantity of biocides was not desirable, and the annual expenditure just for the emulsion products (water, concentrate, biocide and cleaning fluid) was nearly €12,000. This was the situation when Eva Nordenberg, a project manager at Siemens in Finspång, started major improvement work, and Wallenius Water were contacted as part of this work.

Analysis of the current situation and installation

Together with Siemens the engineers at Wallenius Water Innovation started by identifying the problems with the machine in question. The filtration system was analysed, as were the procedures used. A random sample of the process fluid was taken to Wallenius Water Innovation’s laboratory for measurement of the bacterial content. In the lab Wallenius Water Innovation’s Fluid Control System’s effect on the process fluid in use was also validated. The next stage was to measure, dimension and design equipment appropriate to the premises. After the installation on 16 September 2011 lab tests were carried out every other week to ascertain function and measure the effects.

66% cost savings

Ever since the installation of Fluid Control System there has been a tangible difference, both financially and from a health perspective:

- Production disruptions as a result of bacterial outbreaks have been completely eliminated

- 66% cost savings in connection with the product

- The cost of cleaning the machines and the area around them has dropped by 37%

- No use of biocides (or any tank-side biocides)

- No problems with bad smell as a result of bacteria in the fluid

– We are saving both time and money removing bacteria and biocides from the process fluids. At the same time we are improving the work environment and the health of our workers, says Eva Nordenberg.

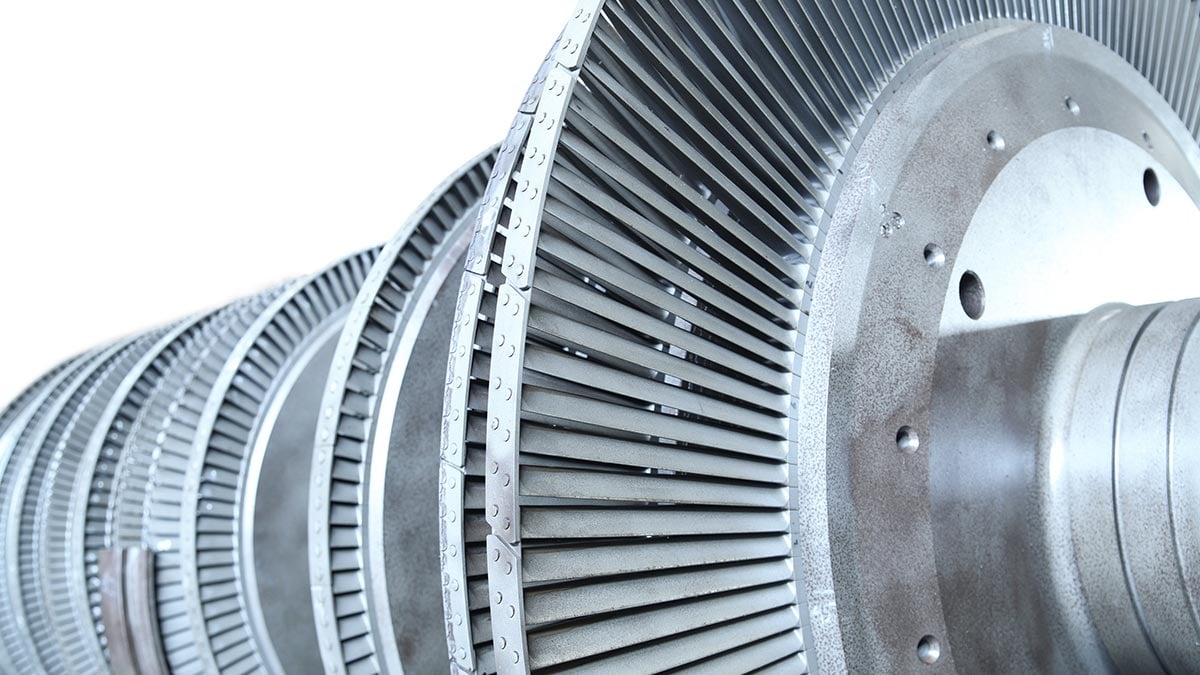

About the process fluid system in Siemens

- Central process fluid system with a total volume of 4,000 litres

- Number of people affected by the work environment: approx. 16 (day and night shift)

- Number of machine tools connected: 2