VTL Precision

The VTL group specialize in the design, development and manufacture of components and sub-assemblies for automotive power train applications. At VTL Precision in Bradley, Huddersfield they are using single machines with tank volumes normally between 400-1500 liters filled with Hocut 4730 and 795 FR.

The VTL group specialize in the design, development and manufacture of components and sub-assemblies for automotive power train applications. At VTL Precision in Bradley, Huddersfield they are using single machines with tank volumes normally between 400-1500 liters filled with Hocut 4730 and 795 FR.

The purpose to install the FluidWorker 100 on one of the VTL machines, M68 EMAG BA 400 was to measure how bacteria contamination could be reduced and controlled over a time of 4-5 weeks. One of the challenges with some of the tanks was that swarf fills up quickly. Every 6-8 month the systems were emptied, cleaned and refilled with new emulsion. When bacteria and pH drop occurred, tank side biocides as well as pH adjuster was added to the system. Occasionally, smell was an unpleasant effect of bacteria. VTL found the FluidWorker interesting mainly due to the HSE benefit it would provide.

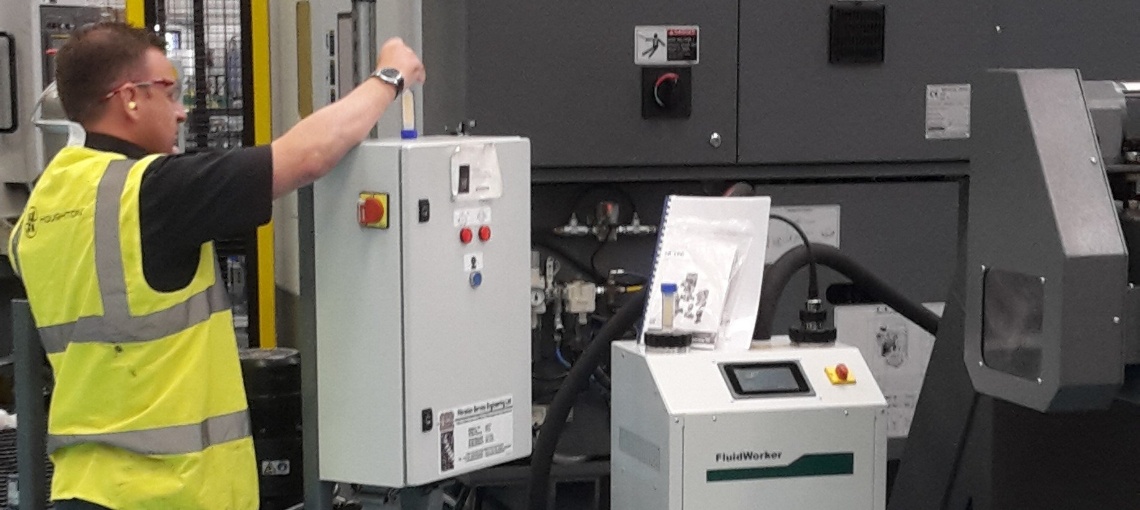

The installation and follow-up was done by Rob Davey, UK Equipment Business Development Manager at Houghton PLC. According to Rob, the FluidWorker 100 was very simple to install, pretty much plug- & -play and the control screen was very user friendly.

As the VTL tank was shallow and filled with swarf, the suction inlet had to be optimized to the cleanest area available. An inlet filter was also added to ensure that the pump wasn´t damaged.

As the VTL tank was shallow and filled with swarf, the suction inlet had to be optimized to the cleanest area available. An inlet filter was also added to ensure that the pump wasn´t damaged.

After installation, July 18th 2018, the bacteria contamination of >10^5 CFU/ml was reduced very quickly. The pH remained on the same level without addition of pH booster. The bacteria remained low during the rest of the trial period, < 10^3 CFU/ml.

The FluidWorker reduced the levels of bacteria very quickly and continued to control bacteria with no biocide additions at all, says Rob.

Please see the trial presentation here: Robs PPT slides

Robs recommendations in brief:

- Ensure that the inlet is put in the clean tank and if needed protected by an inlet filter.

- The controls are password protected so nobody unauthorized can change the setting.

- Check the suction filters regularly along with the pump pressure and maintain above 0.5bar.