Quenching is a critical step as it takes place so late in the production chain. As the products are almost finished, a mistake would be very costly. Very small changes therefore take place in these processes, including the actual quenching fluid.

Using a UV system to reduce the bacteria that grow in the quenching fluid instead of using biocides has many benefits. I have listed the four most powerful here.

#1 You can use UV in the future too

We are facing a massive challenge now that the EU has decided to tighten the rules for quenching fluid additives. A large proportion of the workshops within Swedish industry will be forced to replace their product with one that does not contain biocides.

One solution to the new rules is to find other chemicals that can function as biocides. But how long will it be possible to use them before they also become undesirable? This where the strength of UV systems comes in. As it is a physical treatment rather than chemical, they are exempted from the EU's chemicals legislation. UV systems are a sustainable solution where the EU does not need to legislate in order to protect employees’ health.

#2 UV retains the cooling properties

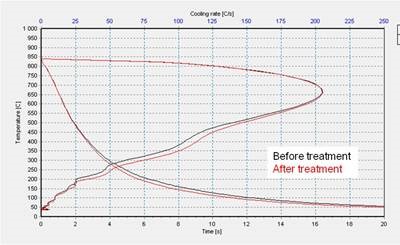

The most common quenching fluids (PAG-based) have proven to be highly UV resistant in our tests. The tests performed were so-called stress tests with the quenching fluid being subject to a much higher dose of UV than it is in normal operation. In field tests through installation in an ordinary quenching system, no effect on the cooling properties has been detected either.

The picture shows: Black: New quenching fluid, Red: Quenching fluid treated with FluidWorker

Biocide additives in quenching fluids have however been discussed for a long time. The fluid's function can be changed by adding chemicals that are not linked to the cooling properties. This can affect the components' quality and lead to a replacement of the quenching fluid.

#3 UV has a constant effect

As the condition of the quenching fluid deteriorates so does the biocides' effect. They therefore have to be added more and more frequently, which finally becomes unsustainable and the quenching fluid is replaced. However, the UV system works continuously and delivers an equal effect regardless of the quenching fluid's age.

#4 UV produces fewer changes

Today's quenching fluids are often changed so that the cooling properties do not deteriorate. This can be as often as every three weeks, and very few fluids can last for longer than three months. If the quenching fluid can be kept fresh for longer, retaining its cooling properties, it would deliver major savings.

Tomorrow's boron-free quenching fluids have proven to have an even shorter service life, which would produce even higher costs for purchasing and destruction. Here a non-biocide-based bacteria reduction would have an even greater benefit.

Summing up

A high and uniform quality of quenching fluid is a key to success. Installing a UV system delivers a long-term and sustainable solution and a substantial cost saving into the bargain. (CS)

Want to learn more about UV purification of metalworking fluids? Download our e-book:

Comment