Up to 200-500 litres of metalworking fluid is often destroyed a week in an ordinary workshop - completely unnecessarily. This is a lot of money over the course of a year. Check whether your workshop has the potential to make savings!

Here are four occasions when metalworking fluid that can be recycled often is sent on destruction:

- There is metalworking fluid in chip bins and containers

- Metalworking fluid is centrifuged from the chips

- The tank is full of chips

- The system is cleaned

How can metalworking fluid be recycled?

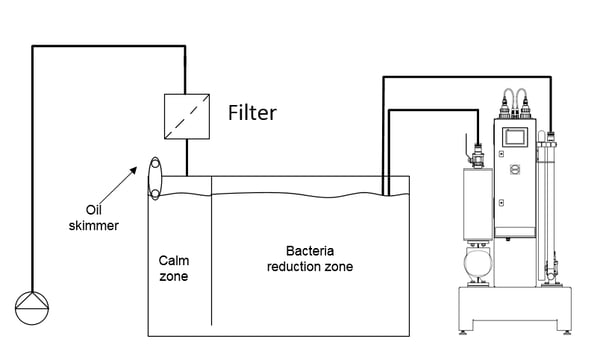

Before the metalworking fluid can be put back into the system its condition must be ensured. A UV-system guarantees that the metalworking fluid is bacteria-free and that it will have no effect upon the system. Below is a proposal where the metalworking fluid from a centrifuge can be restored to the system.

An enormous potential saving

If the fluid is reused, it reduces both the cost of purchasing the concentrate and of disposal. In one Swedish industrial company we have observed potential savings of as much as 7,000 litres in one week. In other words, there is a potential saving of about SEK 850,000 per year, where 51% stems from purchases, 36% from destruction and 13% from internal transportation.

Besides the economic benefits, reuse of metalworking fluid delivers incredible environmental benefits.

How can this happen?

Traditionally, many companies do not look after their metalworking fluid, it causes additional work and it can be difficult to estimate the gains that reuse provides. Certain metalworking fluid suppliers also advise against reusing metalworking fluid with the argument that it can contaminate other fluids and that reuse shortens the service life of the fluid. I agree that this can be the case if you don't ensure that the metalworking fluid is bacteria-free. However, with today's simple methods I see no reason why this enormous potential saving should not be exploited. We do this in conjunction with the customer and serious metalworking fluid suppliers. Contact us for further information.

(JÖ)

Want to learn more about UV and metalworking fluids? Download our e-book:

Comment