Lean aims to maximize customer benefit and minimize waste of resources, which is exactly what recycling of metalworking fluid is about. Every year, 20 million tons of MWF is sent to destruction, and a large part of that could have been used much longer.

Over two million tons of metalworking fluid concentrate are consumed annually in the world. As MWF is diluted 15-20 times, more than 20 million tons will be sent to destruction.

Important environmental aspect

In the UK, 16 million pounds are spent on disposal of MWF every year. The big cost is however not the cost for destruction, but costs for purchases of new concentrates, possible production stoppages and internal transport. In addition to economic aspects, the best way to reduce the environmental impact of metalworking fluids is to reduce the usage by trying to give the fluid as long a life cycle as possible. The life length depends on the fluid's chemistry, process, maintenance and filter equipment.

You can save both money and the environment if you avoid unnecessary changes, such as when cleaning a sump and a chip conveyor, and if you remove fluid from chips.

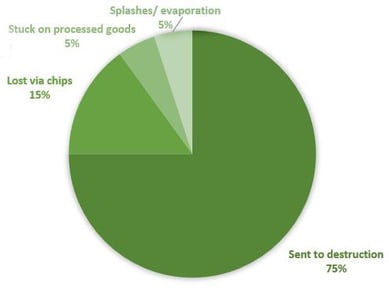

A quarter will disappear during production

A large part of the metalworking fluid disappears along the way. Here is an average estimate:

The amount of waste that is lost via chips is dependent on production and materials. Here are some examples of where the departure to chip can be up to 50 percent:

- Manufacturers with high machining and high chip production.

- Aluminum Processing

- Sawing / Cutting

In the past, it has not been so interesting to try to recycle fluid from chips and at change outs. With new technology in combination with proven methods, it is now possible. Would you like to know more, please follow the blog or contact us.

How much does your MWF cost?

Calculate the total cost with our cost calculator.

Sources:

- "Environmentally friendly mechanical metalworking processes" Nordic Council of Ministers

- "Treatment of spent metalworking fluids"

(JÖ)

Comment