In most cases, UV purification works excellent to reduce bacteria in metalworking fluids, but there are single fluids that are not suitable for irradiating with UV.

We are often asked why we choose to analyse all metalworking fluids before we can express an opinion on which product we recommend or if we recommend one at all. The answer is simple, because we want to be certain that we are selling a good solution.

For even though we have come to the conclusion that the majority of the market's metalworking fluids are compatible with UV-purification, there are those that are not.

So, what are the factors that we look at in order to determine whether UV is a suitable solution for reducing bacteria in the specific metalworking fluid? It involves how dense the metalworking fluid is and whether it contains components that can be broken down by UV light.

Light transmission

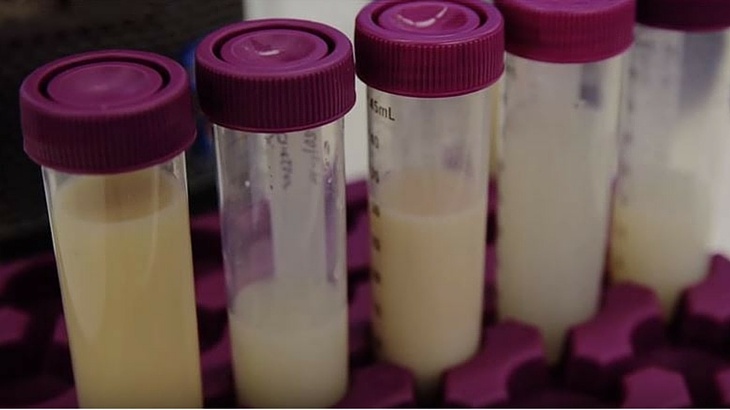

Even though metalworking fluid might look like milk, 90 percent of metalworking fluids have sufficiently high light transmission to enable them to be treated with UV. In these fluids, UV light can be transmitted sufficiently far to be able to reduce a sufficient number of bacteria per passage.

In the remaining ten percent it would require too many UV-lamps to be able to reduce the bacteria, which could lead to a higher cost than for other techniques.

The odd thing here is that it is not possible to determine how dense a metalworking fluid with the naked eye. A fluid that is completely white can be highly permeable, while an almost clear fluid can have a much higher density. It therefore requires a laboratory analysis to be able to provide a recommendation.

UV-stability

Most substances that make up today's metalworking fluids are not affected when they are irradiated with UV. Nine out of ten fluids function excellently together with UV.

However, one tenth of the market's fluids have components that are affected chemically by UV light. If these UV-sensitive components are crucial for the metalworking fluid's function, the fluid should obviously not be treated with a UV-system.

Test first

Experience in combination with a range of lab tests has given us a solid overview of which components are UV-sensitive. However, we nevertheless choose to perform tests for each unique case, so that we can guarantee safe operation of our UV-system. (CS)

Want to learn more about UV purification of metalworking fluids? Download our e-book:

Comment