How much bacteria in process fluid is okay?

Everyone who have been working with process fluids for a while know when it's time to put in actions to prevent bacteria from destroying the fluid. However, new conditions mean that we have to question our previous benchmarks.

Bacteria are everywhere and are generally not dangerous in themselves, depending on the species, concentration and exposure. High levels of bacteria in process fluid can cause production disturbances, corrosion, occupational safety and quality problems.

Therefore, in the industry, green-yellow-red levels have been set.

- 10^0 - 10^3 = Green.

- 10^4 - 10^5 = Yellow - action required. The fluid is not at risk yet but the bacteria might grow rapidly to higher levels.

- 10^6 - 10^7 = Red - take actions. Risky levels, also from a work environment perspective as the fluid begins to change chemically and physically.

Note that since it is a logarithmic scale, the red level is 1000 - 10,000,000 times higher than the green.

Why do the levels look like that?

In the past, many fluids have been relying on one single effective biocide, so toxic that it is now considered dangerous for humans according to the new chemicals legislation (but not prohibited yet). When this biocide has been consumed by bacteria in the fluid, the consequence has been a rapid growth of bacteria as other fluid components have not been able to withstand the bacterial attack.

How do fluids work now?

Today's boron and biocide free process fluids does not have just one single component that protects against bacterial growth but are formulated so that several components of the product in synergy create a good biostatic environment in the fluid. The function of modern fluids is varied, but from experience, we see that formulations where the pH and buffer levels in the biostatic package have been raised, are more bio stabile.

When a well-formulated fluid gets a bacterial attack, the course and consequences are completely different than before. Assuming the right concentration, it will usually be a much slower course, which can at best be adjusted with pH additives or by increasing the concentration a little.

How relevant are the previous levels?

One does not have to be as afraid of bacterial levels up to 10^4 and 10^5 as before, of course depending on how stable the fluid is. New practices are being implemented in Europe, and in Britain the authorities now approve the limit of 10^4 (10,000) CFU.

Of course, measures should be taken to prevent bacterial growth, but avoid unnecessary addition of biocides only to reduce the level. It is important to review the entire system and investigate the cause of the bacterial attack.

New technology can have a slower reduction of bacteria than biocides, but is a long term and sustainable solution - both for the employee and for the production.

Conclusions

- You do not need to have zero bacteria, it's almost impossible and you dare without risk for a short period of time (one week or two) having bacterial levels of 10^5 and long-term 10^4. If you get it lower it's good but it can cost more than it tastes to strive for a zero level.

- With UV technology, you get a slower growth process and long winding variations at a constant low level.

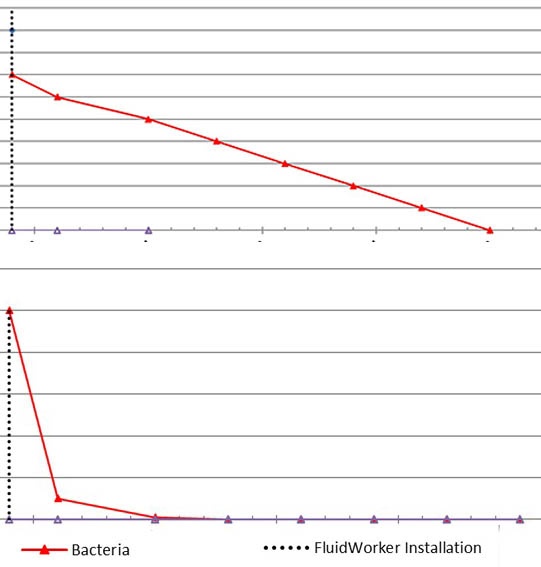

- Sometimes, a logarithmic scale may be misleading. The two graphs below illustrate the same bacterial level described in a logarithmic as well as a numerical (real number).

(JÖ)

Comment