Successful bacteria control with UV light in pre-treatment systems for painting at E. Krieg GmbH in Stuttgart.

In almost all cases, parts to be painted must be clean and free of grease. To achieve this, the components are washed in pre-treatment systems. After washing at 50 - 60 ° C, the parts are usually rinsed with demineralized water and these baths are particularly susceptible to the growth of bacteria.

In almost all cases, parts to be painted must be clean and free of grease. To achieve this, the components are washed in pre-treatment systems. After washing at 50 - 60 ° C, the parts are usually rinsed with demineralized water and these baths are particularly susceptible to the growth of bacteria.

Rinsing off the warm parts also creates a temperature in these tanks that is well above room temperature, creating very good growth conditions for bacteria. Such water baths are particularly suitable for disinfection with the FluidWorker 100, since the liquid is usually very clear and there are no additional additives in the water. A test with FluidWorker 100 at E. Krieg GmbH in Stuttgart has impressively demonstrated this.

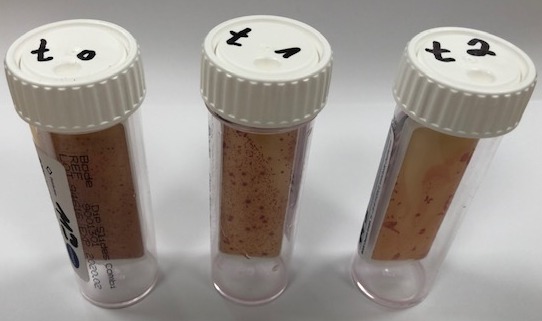

Initial bacteria count: 107

Value after 24 hours: 106

Value after 72 hours: 104

Such problems in pre-treatment systems are widespread and, as a rule, a biocide is added if there is an increased bacterial infection, or the bath has to be changed out. The addition of biocide is of course uncomfortable and nobody has a good feeling about it, but it isn’t necessary anymore. A customer also told me that after the addition of biocide, the pH value often dropped drastically, which led to increased corrosion on the components.

Advantages of UV disinfection with FluidWorker 100 on baths in pre-treatment systems:

Want to learn more about UV purification of process fluids? Download our e-book:

Karsten Lubke började sin karriär som lärling inom mineraloljebranschen. Med en utbildning inom affärsadministration och med många år inom smörjmedelsindustrin har han lång erfarenhet av industriella processvätskor. Han känner väl till problemen med och kraven hos processvätskor och kan vara till stor hjälp för er. Karsten Lübke started his career with an apprenticeship as a mineral oil merchant. With a degree in business administration and with many years working in the lubricants industry, he brings a lot of experience in dealing with industrial process fluids. He knows the problems and requirements of process fluids very well and can be of great help to you. Karsten Lübke hat seine Karriere mit einer Lehre zum Mineralölkaufmann begonnen. Nach dem Studium der Betriebswirtschaft und Anstellungen in der Industrie und dem Schmierstoffvertrieb, bringt er viel Erfahrung im Umgang mit industriellen Prozessflüssigkeiten mit. Er kennt die Anforderungen und Probleme mit solchen Medien genau und kann Ihnen dadurch eine wertvolle Hilfe sein.

Comment